Distillation systems

TD Series Stills

Distilled Water—The Universal standard for Pure Water.

For centuries, distilled water has been the accepted standard for

pure water throughout the world. Its use has been recommended or

specified for literally hundreds of important applications, form

the preparation of water for injectables to critical rinsing steps

in the manufacture of electronic components. Today, distillation

continues to be the most accepted and most widely used method of

providing pure water for science, medicine and industry.

The basic advantages that distillation offers are found in the

inherent simplicity and reliability of the process. In distillation,

impurities are separated from water through the fundamental processes

of evaporation and condensation. Since water stills rely on these

controlled changes of phase rather than on chemical or other complex

techniques, the equipment is very understandable both in operation

and in maintenance. And unlike other methods, distillation does

not require replacement or regeneration of purification media.

Distillation also continues to be the only “single process”

that consistently delivers pure water acceptable for biomedical

applications. In contrast to ion exchange which removes only ionized

impurities but not organics and bacteria, and reverse osmosis which

is only effective in the 90% range, distillation offers generally

acceptable removal of all water impurities, including pyrogen contamination.

USEP Distillation Systems—Standard in Distilled Water Production.

U.S. Engineered Products Thermodynamic Distillation Systems are

recognized the world over for their superior performance and trouble

free operation. Utilizing many unique principles, Thermodynamic

stills maximize the basic advantages of distillation in a design

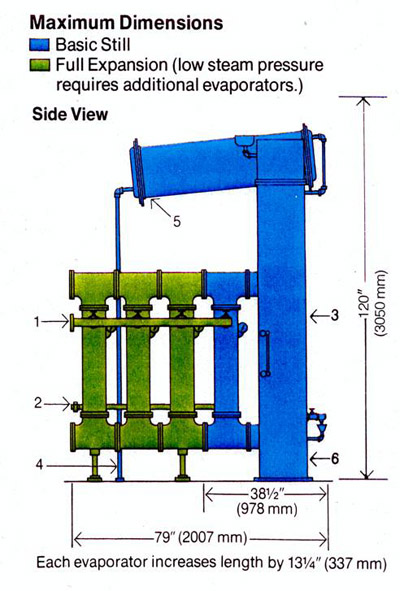

that affords both space-saving economy and unmatched flexibility

for future expansion. Backed by a complete selection of options

and accessories, Thermodynamic stills can be tailored to virtually

any requirement.

Four Thermodynamic families are available in capacity ranges of

15-60 and 50-200 gallons per hour. Within these ranges, Thermodynamic

stills are expandable in increments of 15 and 50 gallons per hour,

respectively.

Each series offers literally hundreds of product configurations

to meet specific feedwater, end use, capital outlay and expansion

criteria. Match your requirements to one of U.S. Engineered Products

standard Thermodynamic models or select components to design the

Thermodynamic system that best satisfies your particular needs.

Contact us for more information info@usengpro.com

610-327-1965

Web site contents © Copyright US Engineered Products 2007, All rights

reserved.

|